Technology Development Center

The TDC isn’t just a testing site; it’s an innovation hub where cutting-edge research, hands-on training, and industry collaboration converge to shape the future of pipeline technology. This facility is a testament to PRCI’s commitment to driving advancements that support the long-term safety and integrity of global pipeline systems.

TDC 2024 Highlights

• Created a ditch for buried pipe with natural and manufactured flaws for multiple guided wave testing projects.

• Expanded in-house skills for standard flaw creation.

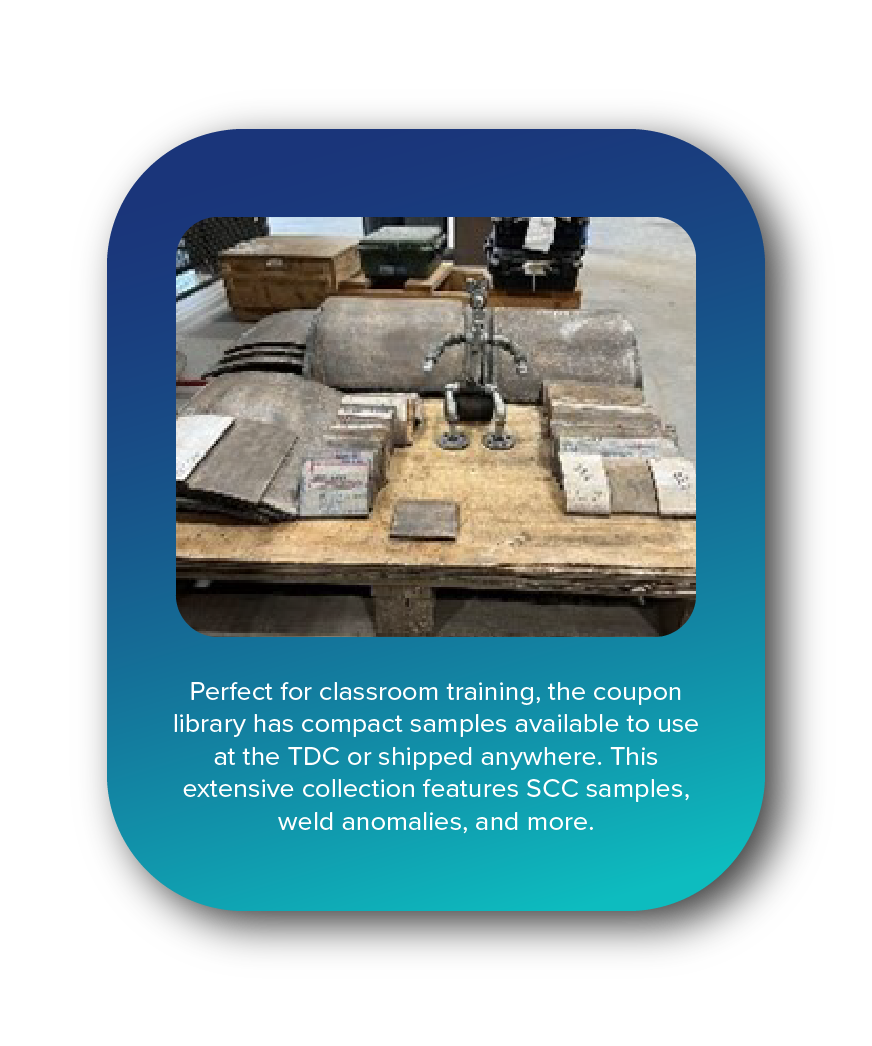

• Curated in house and mobile sample sets to support increased classroom training including the Practical Pipeline Repair Training course.

• The research labs were used 114 times within the year.

• Pull testing occurred on 32 different occasions.

• The flow loop was utilized 17 times.

• Pipe samples were requested 28 times.

• Conference rooms were booked for 101 different occasions.

• Requests for tours continued to increase, totaling 26 visits.

• All office and available lab space was completely occupied.

• LinkedIn audience expanded to over 11,400 followers.

Spanning eight acres in Houston, Texas, the TDC includes a five-acre state-of-the-art pull test facility, a liquid loop facility, and an expansive 20,000-square-foot workshop and test facility. Additionally, it offers 9,000 square feet of office and meeting space, creating an ideal environment for collaboration, testing, and innovation.

Having a single location capable of accumulating former in-service pipe materials with real-world pipeline features and flaws is invaluable to PRCI’s R&D Program and the pipeline industry as a whole. The Technology Development Center (TDC) serves as a central hub for advancing research, offering a space to host industry-sponsored training sessions and hands-on workshops. This unique facility allows researchers, engineers, and industry professionals to collaborate and explore innovative solutions to critical pipeline challenges.

The TDC provides the industry with an independent, third-party site to comprehensively evaluate the capabilities of current tools and technologies. By doing so, it helps guide the development of new, advanced technologies needed to achieve higher levels of pipeline safety, efficiency, and reliability. This facility bridges the gap between research and practical application, pushing the industry towards breakthroughs that benefit operators and the public alike.

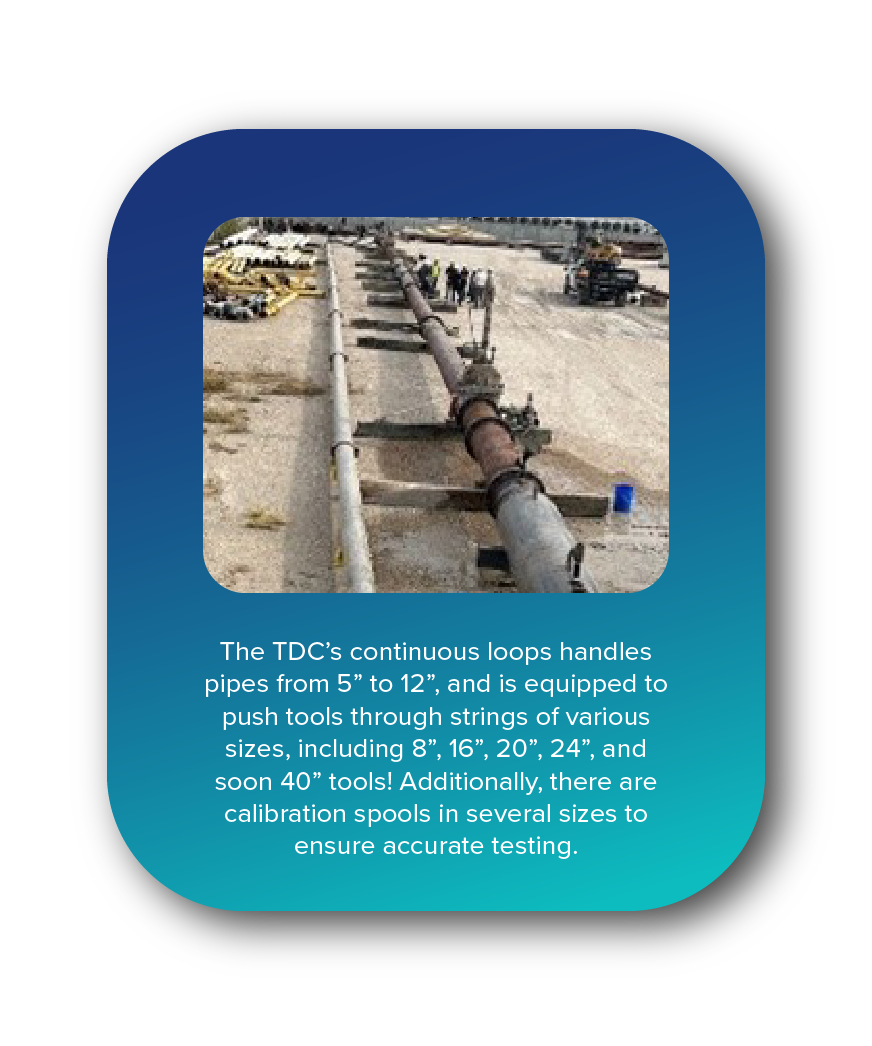

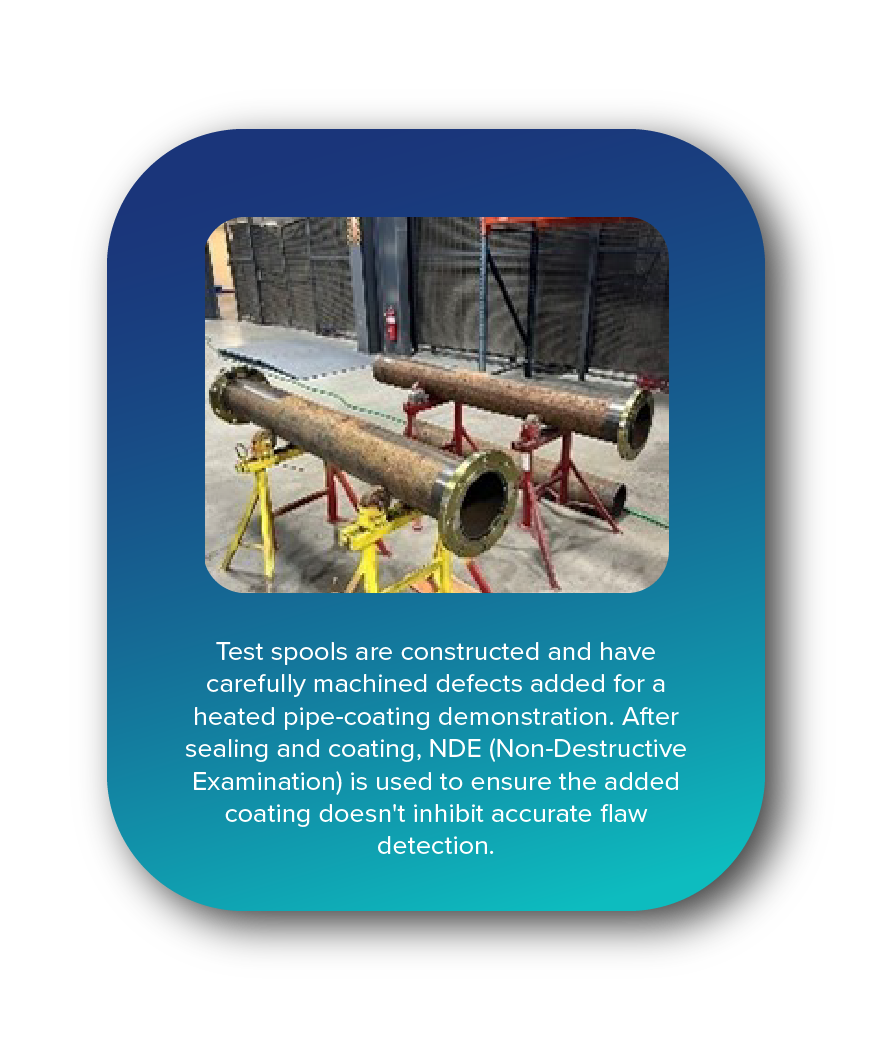

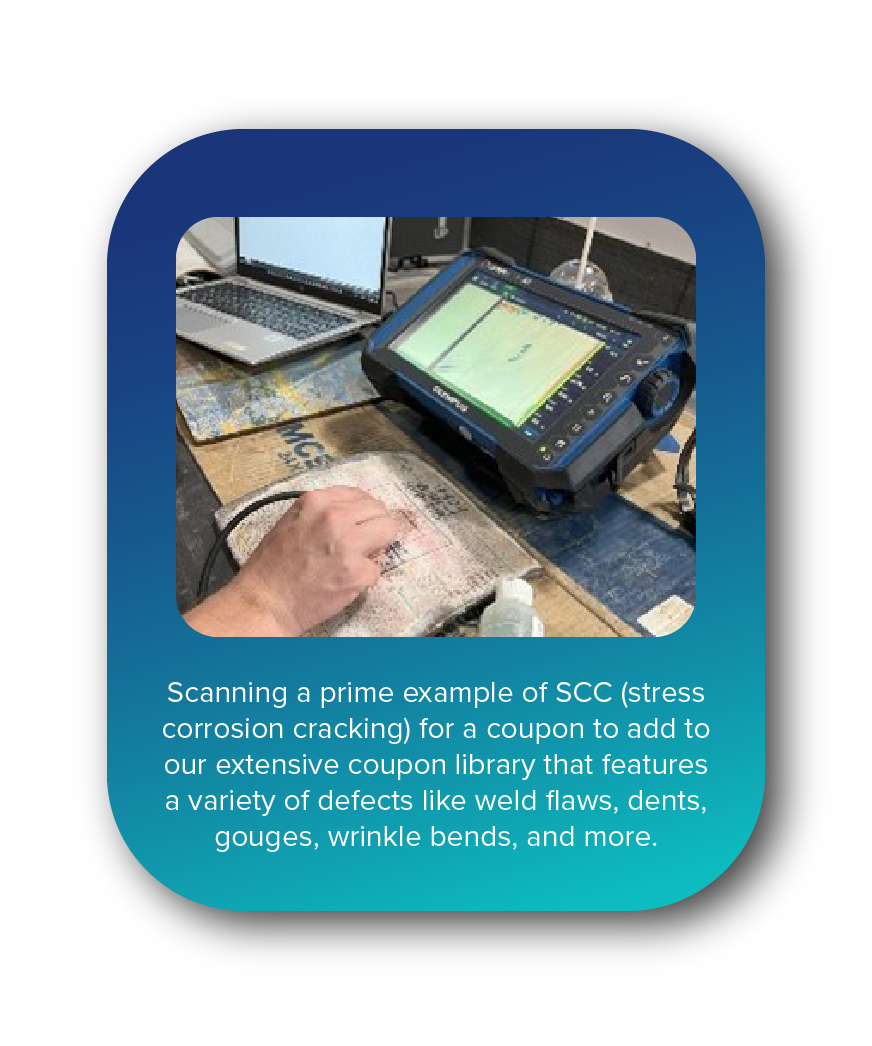

PRCI also maintains an extensive library of over 1,600 pipe samples containing both natural and manufactured defects, which serve as critical assets for research and development. These samples come in a variety of sizes, ranging from small coupons to full joints of pipe in different diameters, providing researchers with a diverse selection of materials to study. Custom pipe strings, up to 250 feet in length, can be constructed to meet specific research requirements. The pull test facility features a high-capacity winch capable of achieving consistent velocities from 1 to 11 mph while pulling over 40,000 lbs, enabling precise testing scenarios.