inspection & Integrity

The Integrity & Inspection Technical Committee improves the reliability of the pipeline infrastructure and ensure the continuity of public service through the development and successful deployment of technologies associated with mechanical damage, pipeline integrity management, and associated inspection technologies.

Chair: Paul Monsour, Southern California Gas Company

Vice Chair(s): Joshua Bremner, Phillips 66 Pipeline LLC

Sean Moran, Williams Companies, Inc.

Chris Newton, Phillips 66 Pipeline LLC

David Xu, Pacific Gas and Electric Company

Shenwei Zhang, TC Energy

“In a very productive 2024, the Integrity & Inspection Technical Committee successfully completed projects to advance integrity management and address integrity gaps with a total of 16 published final project reports and 8 delivered project knowledge-transfer webinars as of November 4, 2024, and 3+ final project reports expected by 2024 year end. This has well exceeded the 2024 target on 10-12 completed projects and 6-8 knowledge-transfer webinars.

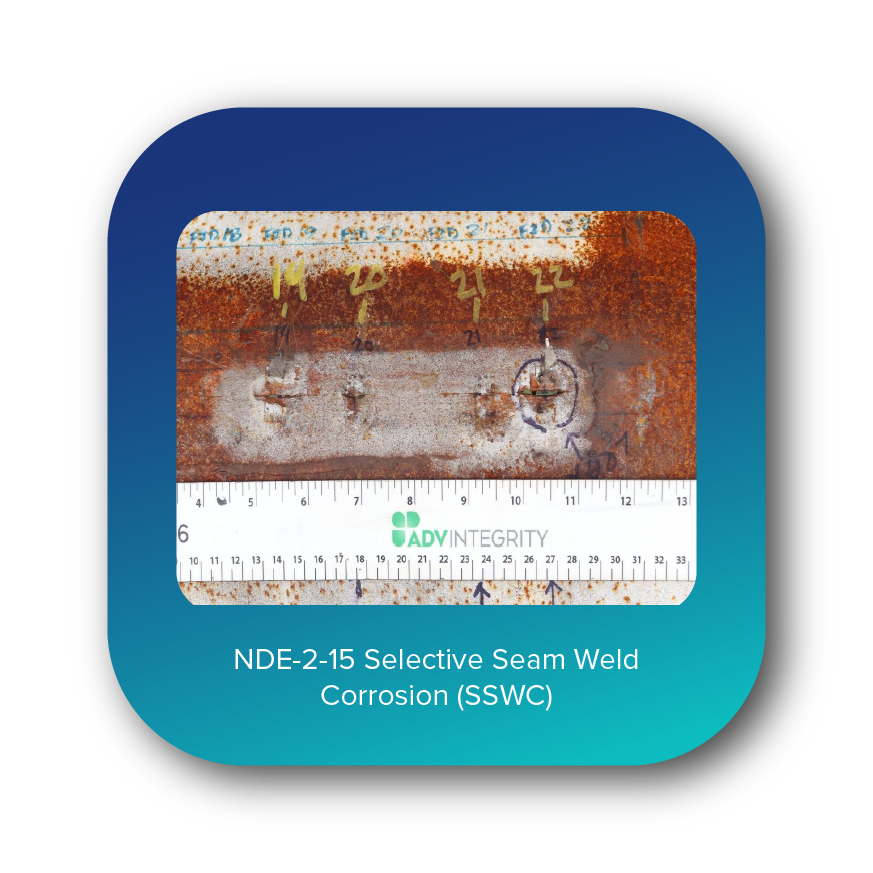

Under the leadership of the passionate project champion and the hardworking PRCI I&I TC PM from initiation to execution, NDE-2-15 was managed diligently with a very focused team effort plus weekly email updates, and delivered a high-quality draft final report in just a little over one year. It is an excellent example of a project that can be executed quickly and efficiently to meet immediate field needs from operators by providing the guidelines for positive identification of Selective Seam Weld Corrosion (SSWC) and proper measuring equipment and techniques for in-the-ditch.

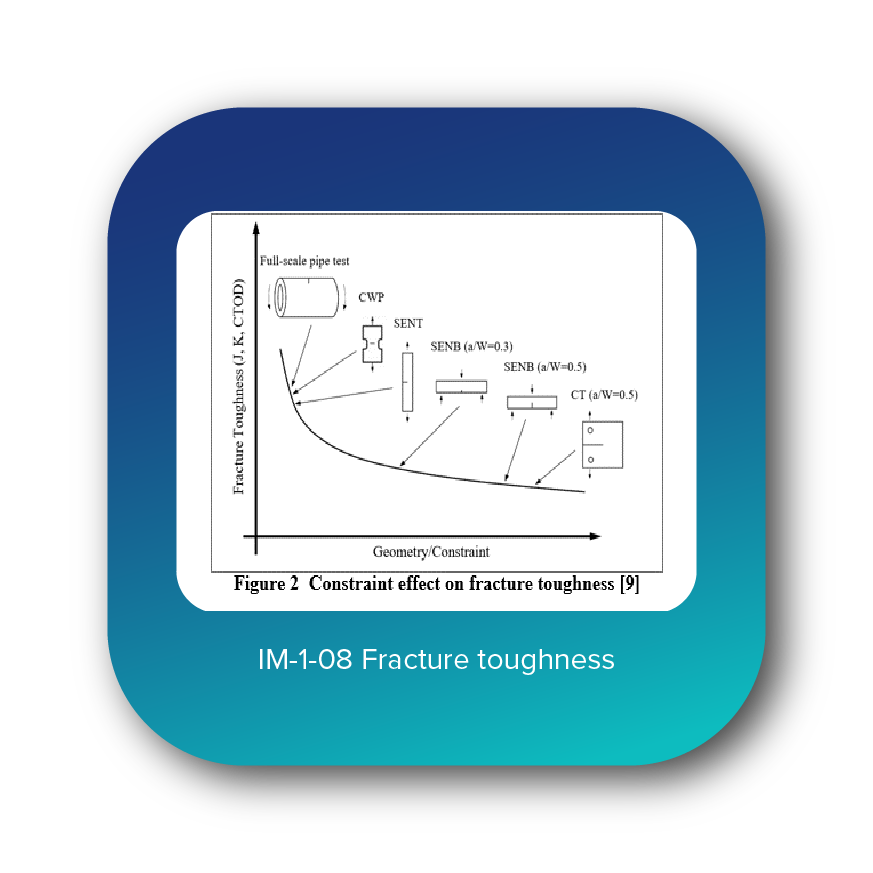

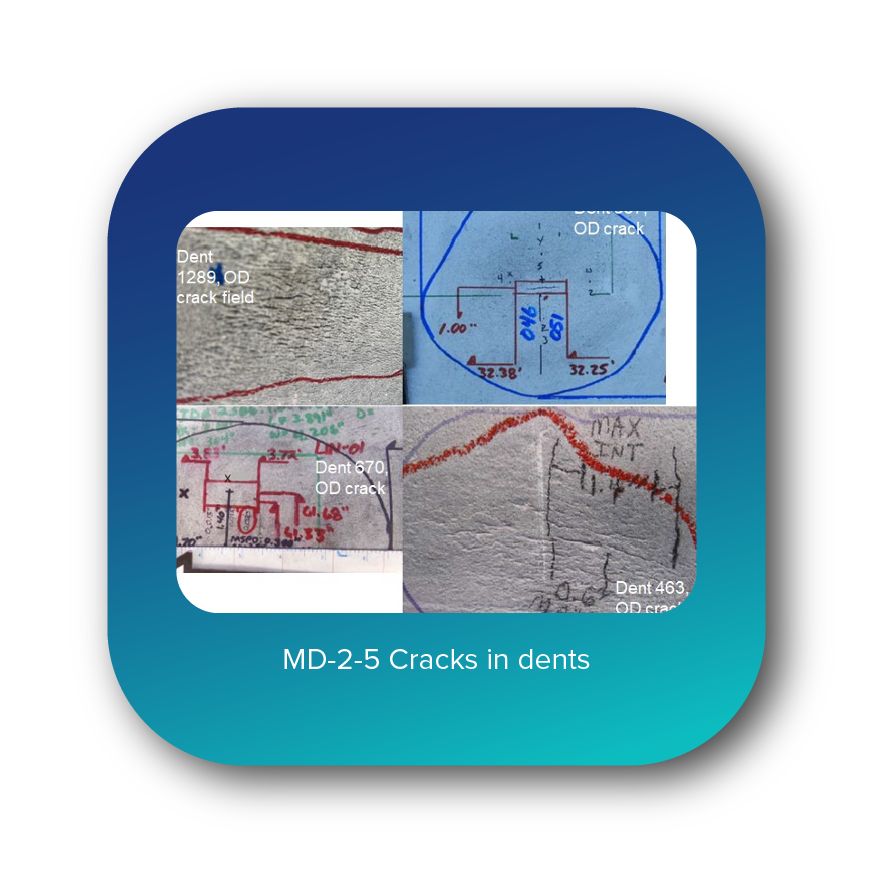

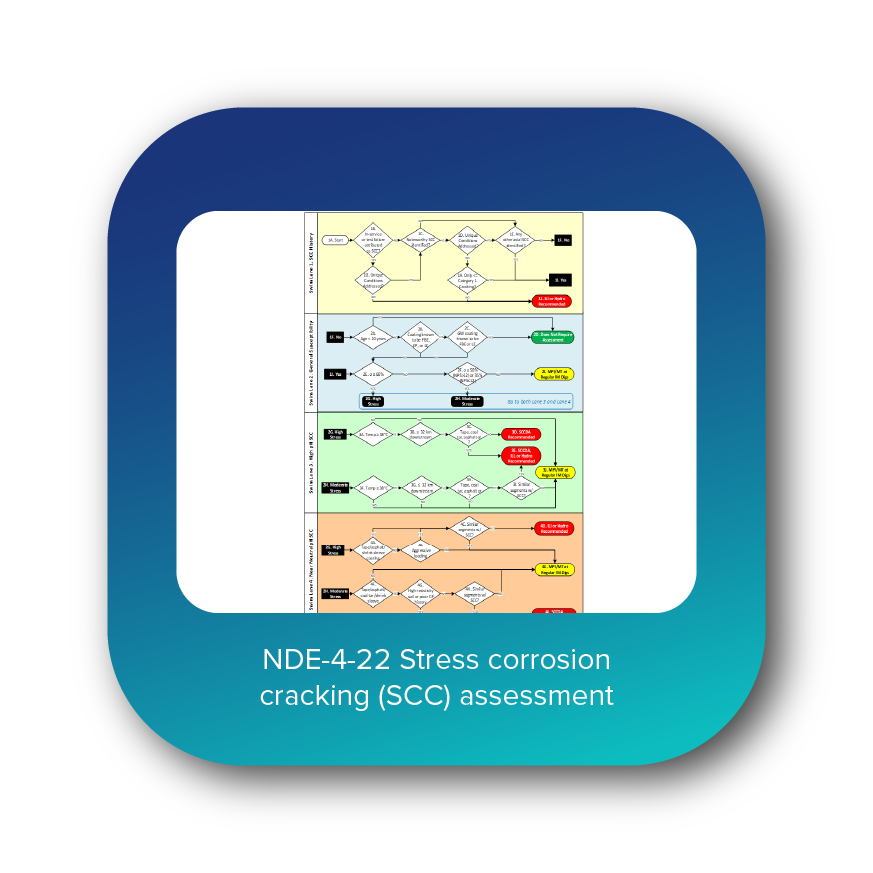

Multiple projects addressing inspection and integrity management of dents, cracks, NDE and ILI performance were completed, and the results will be incorporated for improvements into industry recommended practices. Through round tables and brainstorming sessions as well as collaboration with other technical committees, the I&I TC also updated emerging integrity gaps and created meaningful roadmap projects and/or new ideas in each subcommittee, notably for improved SSWC inspection and management, hard spot detection and susceptibility, risk management, and non-intrusive/above-ground inspection of unpiggable or difficult-to-inspect pipelines.

Thanks to all the committee members for your passion, ideas, thoughts, discussions, active participation and strong support!”

David Xu

-

PUBLISHED REPORTS IN 2024

PR-214-203805-R01 Performance Evaluation of ILI Systems for Dents and Coincident Features ⓟ

PR214-213800-R01 Evaluation of API RP 1183 Dent Fatigue Analyses using In-Service Dents Data ⓟ

PR214-223810-R01 Improvement in Dent Assessment and Management Tools ⓟ

PR276-223814-R01 Pragmatic Application of MegaRule RIN 1 - 192.712 Toughness Values ⓜ

PR328-223813-R01 In Ditch Material Verification for Fittings and Seamless Pipe ⓜ

PR328-223813-R02 In Ditch Material Verification for Seamless Pipe and Fittings ⓟ

PR723-243802-R01 Refitting Paris Fatigue Constants for API 5L Steels and Seam Welds ⓟ

PR727-223805-Z01 Guidelines for When to Perform Crack Detection In-Line Inspection ⓟ

Key

ⓟ Public Access

ⓜ Members Only

ⓦ Webinar Available

ⓢ Software Download